** Comprehensive example below **

Selecting the appropriate wire size is crucial for ensuring safe and efficient electrical installations. In Canada, the Canadian Electrical Code (CEC) provides guidelines and tables to help determine the correct wire size based on various factors. In this article, we will walk you through the step-by-step process of calculating wire size according to the CEC.

Step 1: Understand the System: Before calculating the wire size, it’s important to understand the system and consider factors that will impact wire sizing. Determine the number of conductors required, whether the installation is free air or in a raceway/conduit or cable, and whether it is underground. Match the configurations described in Sections D8 to D11 of the CEC.

Step 2: Pick the Appropriate Table: Based on the system configuration, refer to the appropriate table in the CEC to determine the wire size. Here are the relevant tables to consider:

-

Table 1: Single free air copper conductors

-

Table 2: Three or fewer copper conductors in a raceway or cable

-

Table 3: Single free air aluminum conductors

-

Table 4: Three or fewer aluminum conductors in a raceway or cable

-

Table 5A: Ambient temperature above 30°C for single free air copper conductors

-

Table 5B: Ambient temperature above 30°C for single free air aluminum conductors

-

Table 5C: More than three conductors installed in a raceway or cable

-

Table 5D: Installed in ventilated cable tray or ladder tray (applies to certain scenarios)

-

Tables D8A to D11B: Underground conductors as per configurations in Diagrams D8 to D11

Step 3: Consider Derating Factors: If the ambient temperature is above 30°C, derating factors need to be applied. Refer to Table 5A or 5B based on the conductor type and ambient temperature conditions. Additionally, consider derating factors specified in Table 5D for installations in ventilated cable trays or ladder trays.

Step 4: Evaluate Conductor Spacing: For installations with multiple free air conductors, evaluate the spacing in relation to the largest cable diameter. Refer to Table 1 and 3 if the spacing is less than 25% of the largest cable diameter. For spacing between 25% and 100% of the largest cable diameter, consult Table 5D. If the spacing is more than 100% of the largest cable diameter, Tables 1, 3, and 5D can be used.

Step 5: Consider Conductor Quantity: For scenarios with more than four free air conductors in contact or more than three conductors in a raceway or cable, use Table 2 and 4, or Table 5C respectively. However, neutral conductors carrying only unbalanced current and bonding conductors should not be counted.

Step 6: Bare or Covered Conductors in Free Air: For bare or covered conductors in free air, refer to Table 66 in the CEC to determine the appropriate wire size.

Example

What should size of 3 RW90 copper conductors installed in free air where the maximum allowable ampacity is 100A? The conductors will be in a mechanical room where the ambient temperature is 40°C. and the spacing between the conductors is equal to 25% of the diameter of the largest conductor.

-

Here we are using RW90 cables, so the temperature limitation of the conductor terminations is 90°C. However, it is important to make sure that the equipment termination rating is 90°C. If not, you’ll have to use a transition of minimum 1200mm (heatsink). Note: most electrical equipment is rated for 75°C.

-

90°C column

-

-

Copper conductors in free air.

-

Table 1

-

-

Based on the 90°C column of Table 1, a #6AWG wire is suffice for 100A.

-

The ambient temperature of the room is 40°C, therefore we would need to apply Table 5A for the derating factors as the temperature is above 30°C.

-

40°C ambient temperature and 90°C termination rating results in a derating factor of 0.91.

-

-

The 3 conductors are spaced at 25% of the diameter of the largest conductor, therefore we would need to apply Table 5D for the derating factor as the spacing is less than 100% of the largest diameter.

-

1 vertical layer and 3 conductors horizontally spaced between 25% and 100% of the largest diameter results in a derating factor of 0.87.

-

-

Apply the derating factors to the 90°C column of table 1 to find the required wire size.

-

140A * 0.91 * 0.87 = 110A > 100A

-

Therefore a #4AWG would suffice

-

-

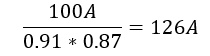

A better way to apply the derating factors, is to divide your ampacity by the derating factors to get a new ampacity, and then consult the table.

Now that you applied the derating factors to your ampacity, you consult the 90°C column of Table 1 to get the required wire size:

#4AWG